Slim bass clarinet mouthpiece

Slim bass clarinet mouthpiece

One of the ideas that I have with bass clarinet mouthpieces is to make a very slim mouthpiece. Compared to a Bb mouthpiece or a tenor saxophone mouthpiece the bass clarinet is very thick and for me it results in excessive saliva formation. So I want to find out what happens when I make a slimmer mouthpiece.

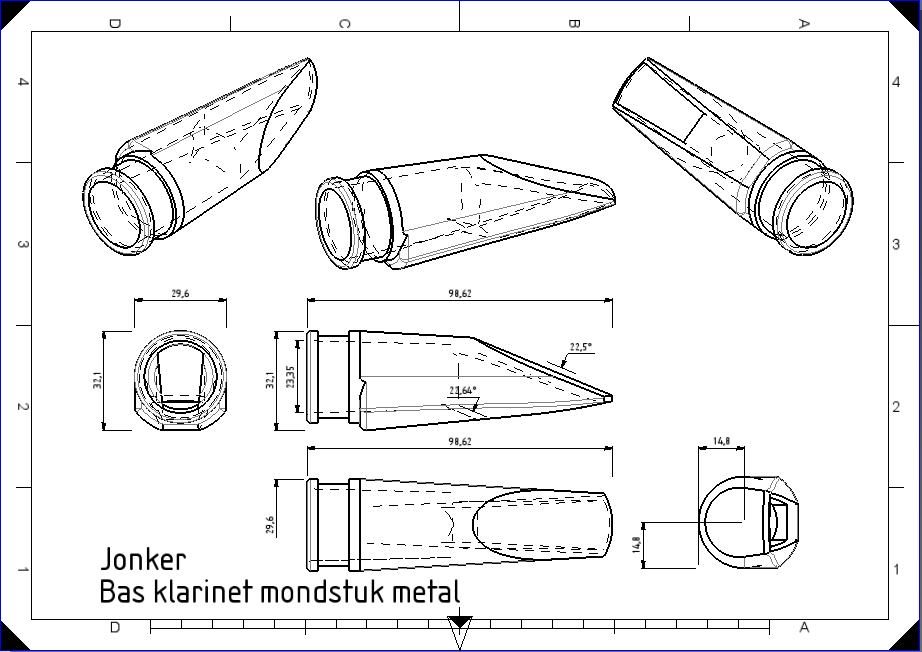

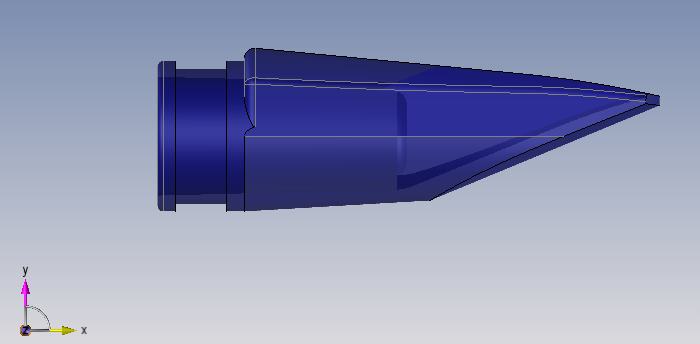

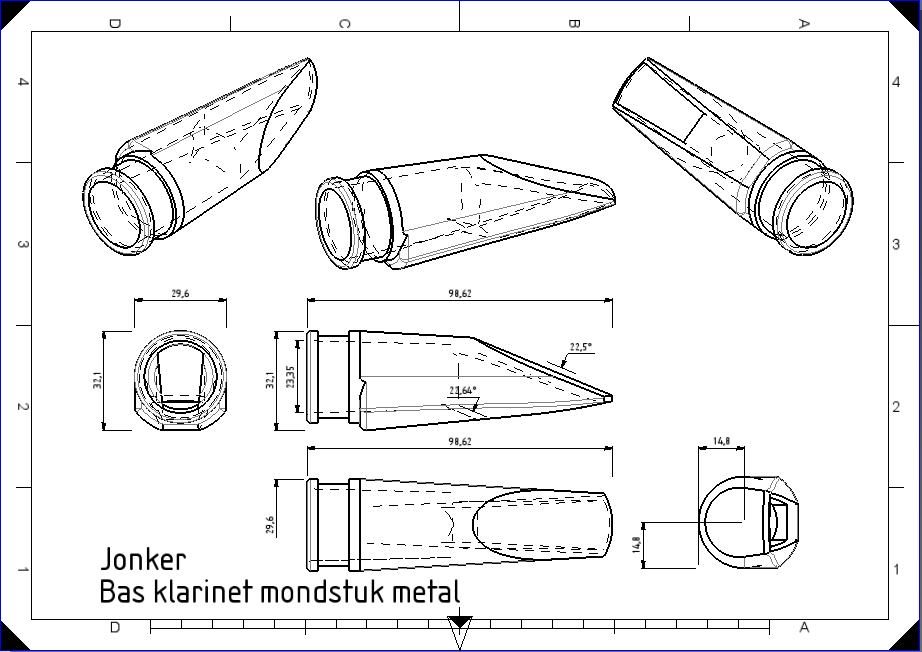

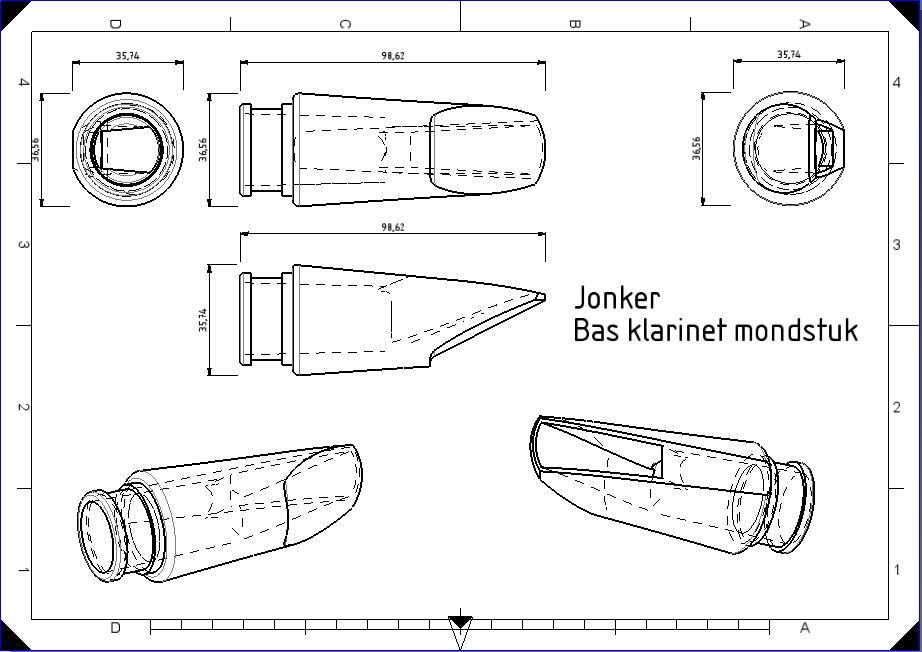

The idea is to take a standard mouthpiece, keep the chamber, bore and table unmodified and see how far the external dimensions can be reduced. Maybe it will be necessary to produce the mouthpiece in metal.

The figure above show that the outside beak is reduced to a few mm thickness and that the shank is seamlessly transferring to the top of the back of the barrel.

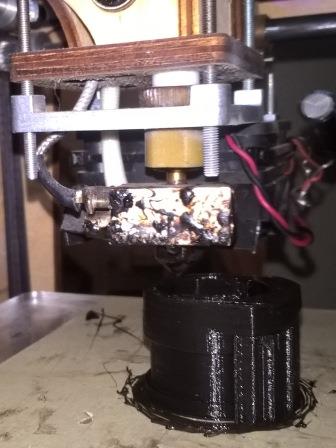

The prototype is made on my old Ultimaker Original 3D printer.

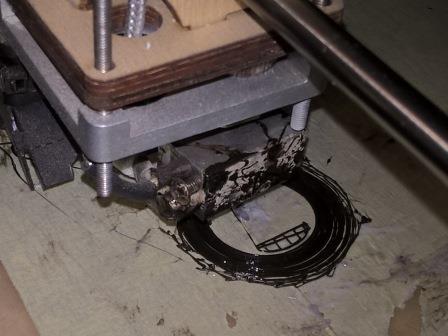

The brim to hold the mouthpiece on the build plate

After one and a half hour it is not even half way. Each layer is 0.1mm thick.

The prototype is finished after 5 hours of printing. Now I have to polish the part in water.

After 10 minutes polishing with 400 sandpaper I do the first (yes I am impatient) playing test and it surpises me in a positive way. It sound really good in the lower register. In the higher register it tends to squeeze a little. I think it needs a more accurate postprocessing to improve that. But I also found out that some other things need to be improved. A second prototype is needed. The beak and the tiprail have to be more curved and the diameter of the shank must be increased. Maybe the last thing is caused by inaccuracy of my 3D printer. But despite of that 3D printing is ideal for prototyping.

And why not; make the next prototype out of blue PLA.

The first impression is quite good. What is next is a long periode of test playing an maybe ask some players to try one too.

-1666348987.jpg) We zijn het adres voor het huren van basklarinetten en saxofoons.

We zijn het adres voor het huren van basklarinetten en saxofoons.