Corrective bending of saxophone keys

Corrective bending of saxophone keys

According to many repairers the basic method of adjusting the saxophone key alignment is by means of bending. The philosophy behind it is that the saxophone is designed so that the combination of the right pad thickness and proper alignment of the keys and tone holes should be a sealed instrument.

(English is partly from automatic translation and may need to be corrected)

Intensive use of the saxophone can cause (squeeze hard) the keys no longer to be properly aligned with the tone hole. Then the instrument may need to be restored to the originally intended state.

Until now, I used only very little bending correcting because of the risk of damage. The main reason is that I started out with quite molested Conn New Wonder where bending sometimes lead to deformations of the cups and sometimes even to breaking of the key arm. But apparently it is a matter of policy.

What requirements I suggest for bending:

- The tone holes are and remain flat and undamaged;

- The cups are and remain flat and undamaged;

- The bending tools leave no damage behind on the saxophone;

- Correction can be carried out with the keys on the saxophone;

- Correction is to be carried out with as little as possible removal of other keys.

What experiments on an unlacquered saxophone delivered a first step towards a method and a design of an associated set of tools.

General

Grip pliers for valves

This grip rod is the first tool I (re)made myself adjusted as follows:

- the inside of the mouth is polished in the mouth

- a recess cut is made that fits around the arm of a saxophone valve.

This clamp is suitable to fix the hinge of the saxophone key.

An improvement that can be made is to drill a hole of 5mm in the inside of the plier mouth. It reduce the damages to the hinge and gives an improved grip.

Lateral correction

If valves need a sideways correction, you can do so by using the following bending iron. The bending tool engages on two points which will give relatively little force exerted on the hinge. This can be further reduced by fixing the hinge with the grip pliers for mentioned before.

Lateral torsion

If a key suffers from a laterally torque, it must be bent so that no excessive forces are exerted on the hinge. This should be possible in principle, with two flat mouth pliers with a relatively wide mouth. With one you fixe the arm of the key and prevent power on the hinge. With the other you correct the torque. The jaws of the inner side should be polished and have rounded corners.

Alignment in the direction of rotation

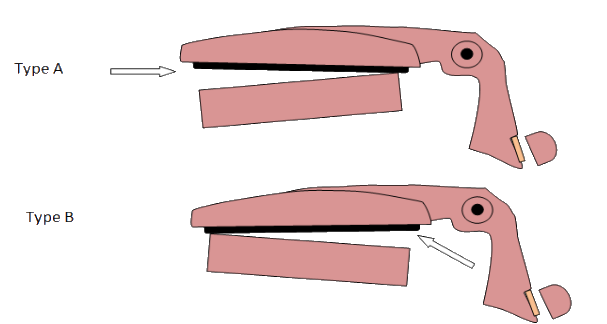

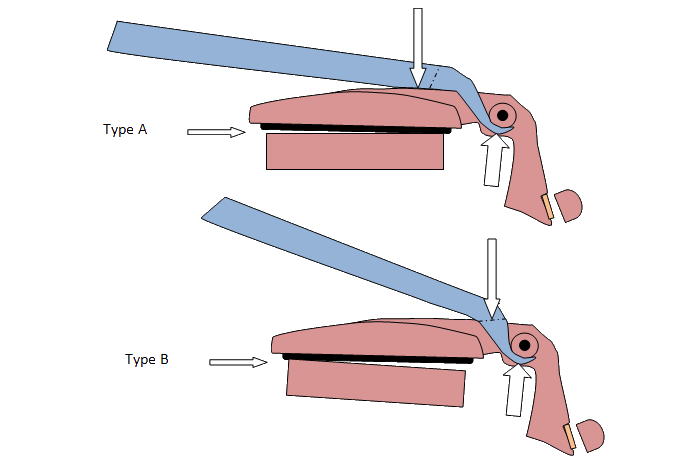

In the direction of rotation of the valve incorrect thickness of the pads can cause improperly closing of the keys. When the pad is too thick, the key closes early at the rear of the tone hole, closest to the hinge, and creates a gap at the front (type A ).

When the pad is too thin, the key closes at the front of the tone hole, farthest from the hinge, but not yet at the rear and creating a gap at the rear.

A commonly used method in the past, but not a quite ideal way to correct this is laying a metal bulge at the place where the tone hole closes first and then pressing down the other side of the cup. The expectation is that the cup hardly suffers from the force and will not bend. I did one experiment with a a flat cup. When I inspected the flatness of the cup again ( I put the cup on a flat metal strip and held the area up to the light), the opposite was true. The cup can easily be deformed by this action and become slightly curved. That does not have to be bad. If the gaps will be closed this is OK. But in a subsequent revision it may cause problems and the question if this solution will remain stable. Another disadvantage is that the tone hole may be damaged by the metal strip . This can be avoided by using, a softer material, such as plastic or cork. Finally, the pad at the location of the thickened portion is strongly pressed and the possibility arises that after some time the pad comes back in the old form again resulting in a small gap.

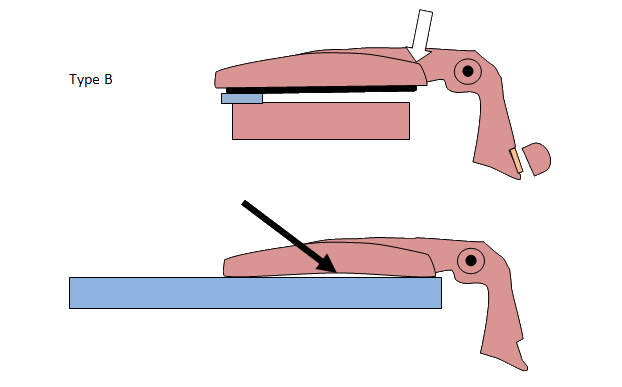

The deviation from the type A and type B can be corrected by adjusting the curvature of the arm to the cup in the part of the arm between the cup and the hinge.

The resources for correction of the deviations of type A and B are very similar. Only the point of application of the bending irons on the arm of the key are different. To correct the deviation from type A pressure must seize just past the transition to the cup. To correct the deviation of the type B, the pressure should be just before the transition to the cup.

Inconvenient is that not all of the keys have the same arm length and, therefore, quite a few different sizes bending irons are required in order to properly carry out the corrections.

Correction of synchronization of the primary and secondary valves

The primary keys are cis on the left hand and fis on the right hand. The keys are connected by a link to the secondary valves and have to close simultaneously. This closure can be controlled by cork and sometimes by set screws. But sometimes the deviation is large and a correction is necessary.

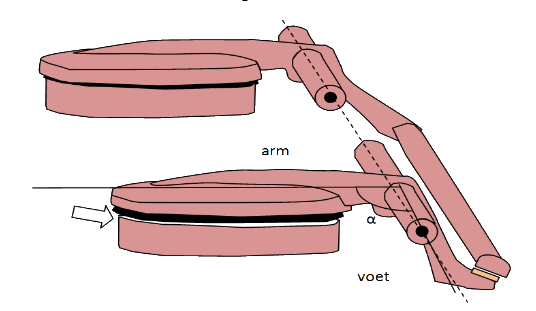

The angle α between the arm to the cup and the foot must sometimes be increased and sometimes decreased.

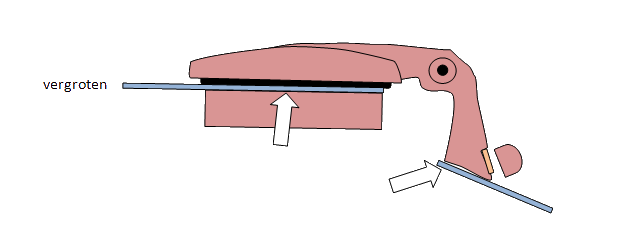

The angle can be increased by pushin up a slick path of the correct size below the pad and a metal plate under the base (foot) of the key and the body of the saxophone. The latter prevents a dent occurs when the cup is gently pushed up.

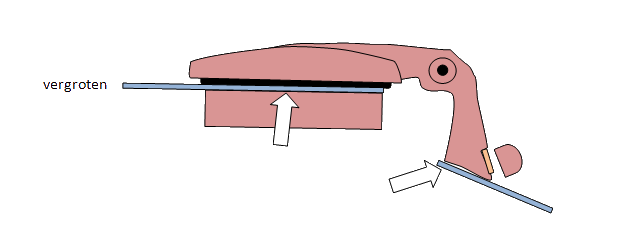

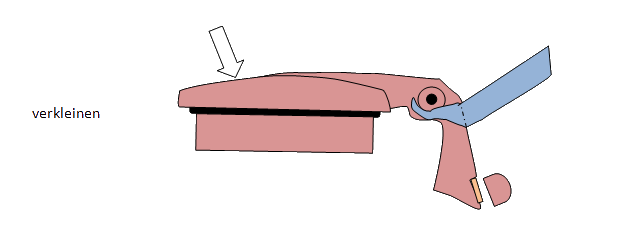

The angle is decreased by pressing the cup to the tone hole and bending the base (foot/voet) down by a well fitting bending iron.

The next step is to make a nice polished set of these bending tools. To prevent damage to the saxophone I'm thinking about about coating them with polyurethaan glue too.

-1666348987.jpg) We zijn het adres voor het huren van basklarinetten en saxofoons.

We zijn het adres voor het huren van basklarinetten en saxofoons.